This guide discusses the cleaning of cut resistant apparel made with DuPont™ Kevlar® brand fiber using standard industrial cleaning practices,including the impact of cleaning on performance。This information is applicable to other types of apparel manufactured with Kevlar® fiber. Before initiating a cleaning program, consult the protective apparel supplier regarding any special cleaning requirements for the products under consideration.

Effect of Laundering and Dry Cleaning on Glove Performance

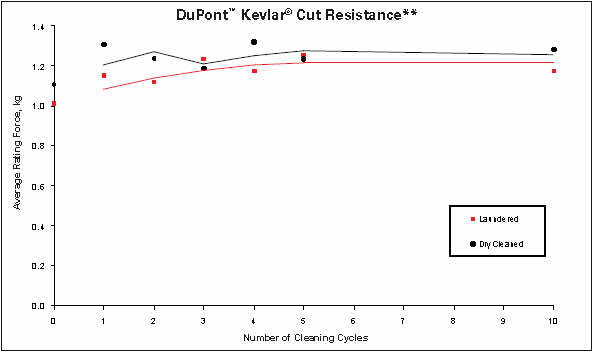

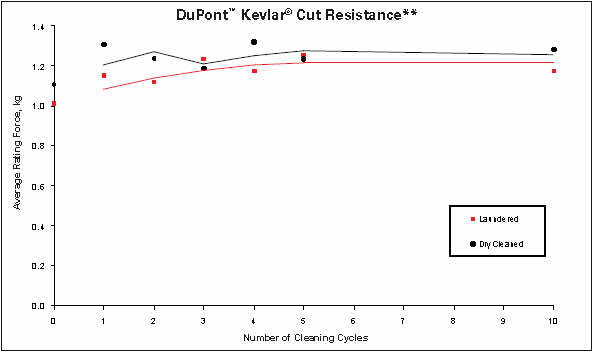

Laundering and dry cleaning have no significant impact on the cut resistance of gloves made of 100% DuPont™ Kevlar® even after 10 consecutive cleaning cycles. A typical glove is expected to undergo less than ten cleaning cycles due to normal wear and tear. Shrinkage, weight loss, changes in yarn tensile strength and changes in color related to staining from soil or the cleaning method may be observed. Although the strength of Kevlar® yarns used in protective apparel, e.g. gloves, gradually decreases with successive cleaning cycles, the cut resistance is not impacted, as illustrated in the charts below.

On average, the typical glove shrinkage observed is 3% or less over 10 cleaning cycles when laundering or dry cleaning gloves made of 100% Kevlar® brand fiber. Shrinkage is primarily due to the knit structure and the gloves will expand back to normal size when placed on the hand.

Cleaning procedures can usually be developed to remove most industrial soils. In some applications protective apparel can become contaminated with epoxies, adhesives, paint, or other materials that are difficult to remove. A standard for retiring gloves due to soiling or contamination should be established.

Effect of Bleach on Kevlar® Glove Performance

Kevlar® brand fibers are resistant to many chemicals and solvents. However, strong acids, bases, and certain oxidizers, like chlorine bleach* (sodium hypochlorite), cause rapid degradation of the fiber. Although chlorine bleach (e.g. Clorox® Regular Bleach) cannot be used with Kevlar®, oxygen bleaches such as sodium perborate (e.g. OxiClean®) can be used without issue. The table on the following page shows the impact of both chlorine and oxygen bleach on the yarn strength and cut resistance of Kevlar® gloves.

When gloves are laundered repeatedly with chlorine bleach, DuPont™ Kevlar® yarn loses the majority of its strength and the fabric can be torn by hand. When oxygen bleach is used, the yarn loses less than 10% of its original strength. Under these conditions, the Kevlar® product performs in a similar fashion to what is observed when laundering without bleach. As illustrated in the charts on page 1, changes in Kevlar® yarn strength have little impact on the cut resistance of the product.

Gloves Incorporating Other Materials

It is important to note that while apparel made of 100% DuPont™ Kevlar®, Kevlar® Clean, and Kevlar® Armor brand fibers can be laundered or dry cleaned without issue, products incorporating other materials such as companion yarns, coatings, cuff elastic, etc. may require special care. Rubbers, plastics, and elastic material used in gloves and other protective apparel may be sensitive to some detergents, cleaning additives, or dry cleaning solvents. This may result in hardening or the loss of other functional properties after repeated cleaning. Selection of the correct cleaning process is vital to maximize the useful life of your protective apparel. Consult your supplier or cleaning professional to determine whether or not the products you are using have special cleaning requirements.

Life Cycle of Protective Apparel Made with Kevlar®

Gloves made of Kevlar® fiber are highly resistant to cut damage from sharp edges on objects such as sheet metal and glass. As with any protective apparel, damage due to wear may occur with normal use. The average service life of protective apparel made from Kevlar® is determined by several factors including: fabric basis weight, article construction, nature of the hazard during use, the cleaning/repair program, and the standard for keeping gloves in service, which is established by the user. Protective apparel made with Kevlar® can often be repaired by mending the damaged area with thread or patches made of Kevlar® brand fiber.

Effective Glove Programs

An effective glove cleaning program requires a good control system to ensure that dirty gloves are properly accounted for and recycled or replaced after cleaning. Simple measures, such as trading used gloves for clean or new gloves, can be taken to implement this. An agreement should also be established with your cleaning service regarding the cleaning procedures used, cleanliness level required, inspection/repair services provided, and the process for removing damaged apparel from service. In addition, outlets exist for recycling the 100% Kevlar® fiber content of protective apparel when the items are no longer fit for intended use. However, this recycled fiber should not be used for protective apparel applications.